What is NPSH?

The most misunderstood concept in the pump world is net positive suction head (NPSH). Process Engineers need to be concerned about this issue, because mistakes with respect to NPSH available (NPSHa) calculations are all too frequent and expensive to correct.

Definition of NPSH, NPSHa & NPSHr

NPSH

NPSH stands for Net Positive Suction Head and is a measure of the pressure experienced by a fluid on the suction side of a centrifugal pump. All values are in “Head” (meters) as it is a fluid-independent property. A pump will lift different fluids to the same height irrespective of their densities.

NPSHa

NPSHa is measured at the pump centerline. NPSHa is the liquid’s available energy level at the inlet of the pump. The liquid will flash to vapor if there is not enough NPSHa.

NPSHa is the amount of NPSH that the system has available at the eye of the pump impeller. It is entirely a function of the liquid, its properties, ambient conditions and the suction system design and geometry. Essentially, the calculation is about the upstream system of pump (suction system) and has nothing to do with the pump. The system engineer (owner/engineer consultant) is responsible for the calculation and manufacturers are normally not involved in the calculations.

NPSHr

NPSH required (NPSHr) is most commonly determined by the pump manufacturer by empirical methods and using standards and specifications. NPSHr values are normally reported on the performance curves for the pump. NPSHR is the suction pressure necessary to ensure proper pump operation. It is purely a function of the pump design, and although it can be calculated, it is more accurately determined by actual testing.

Sometimes, we also refer to term NPSH3. NPSH3 and NPSHr are basically the same entity. At the given operating point of head and flow, the pump is already to some extent cavitating due to insufficient NPSH and the developed head has dropped by 3 percent while the flow rate is fixed at some value.

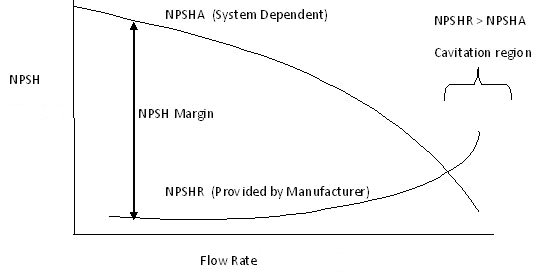

What is a safe NPSH margin?

It is impossible to design a centrifugal pump that exhibits absolutely no pressure drop between the suction inlet and its minimum pressure point, which normally occurs at the entrance to the impeller vanes. Therefore, all pump systems must maintain a positive suction pressure that is sufficient to overcome this pressure drop. If the pressure is not sufficient, some of the pumping fluid will change state from liquid to vapor and cavitation is introduced.

Cavitation also results in vibration and noise in the pump, placing greater strain on the drive shaft and other components, and in downstream pipework. This can lead to greater maintenance costs and a higher incidence of pump failures.

NPSHa must exceed the pump’s NPSHr rating for the chosen operating conditions to ensure that cavitation is avoided. Normally, a safety margin of 0.5 to 1m is required to take account of this and other factors. Depending on the pump design, HI recommends an NPSHA / NPSHR margin of 1 to 2.5.

Calculating NPSHa

Following information is needed to calculate NPSHa:

- Absolute pressure on or at the liquid surface

- Static head, which is the vertical distance from the top of the liquid surface to the pump centerline

- Vapor pressure of the liquid being pumped

- Friction head due to resistance offered by flow path

NPSHa = Pressure absolute (h a) - Vapor pressure absolute (hvp)+ Static height of the liquid (hs)- Frictional losses (hf)

Where, pressures are in absolute values and unit of meters

The first term in the equation represents the value for the absolute pressure (ha) above the liquid surface in vessel / tank.

Note that variations in the atmospheric pressure can and will affect the NPSHa value if the tank is atmospheric tank.

The second term in the equation is the vapor pressure (hvp) for the liquid at this given temperature. To get the vapor pressure value. Same can be referred from HYSYS simulation model (hydrocarbons) or Steam table (water).

The third term in the equation is the static head (hs). This is a vertical distance from the surface of the liquid to the center line of the pump. As worst case scenario, usually lowest level (LAHH) in the tank/vessel is considered.

The fourth term in the equation is the friction loss (hf) in the piping. For a given liquid flow rate, there will be friction losses for the pipe length and fittings like elbow, bends, reducers/ expanders, the valve, the exit loss from the tank / vessel nozzle and the entrance loss into the pump.

NPSHr measurement by Manufacturer

Manufacturers test pumps under conditions of constant flow and observe the discharge pressure (differential head) as NPSH (the suction pressure) is gradually reduced. These tests are usually performed with water at 20°C. NPSHr is defined as the value at which the discharge pressure is reduced by 3% because of the onset of cavitation.

In Nutshell :

NPSH (Net Positive Suction Head) is a measure of the pressure experienced by a fluid on the suction side of a centrifugal pump. It is used to avoid running a pump under conditions which favors cavitation. NPSHr (NPSH Required) and NPSHa (NPSH Available) are important terms in NPSH values:

- NPSHa is a system property calculated from the suction-side system.. It is basically the suction pressure less the vapour pressure of the pumped fluid at that point.

- NPSHr is a pump property provided by pump manufacturers as the suction pressure at which cavitation has already reduced pump performance by 3%.

To avoid cavitation, it is required to ensure that NPSHa exceeds NPSHr by a sufficient safety margin.

Share

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

1

Sad

1

Wow

0

Wow

0