Ensuring Safety with Pressure Safety Valves

Pressure is a critical factor in various industrial processes, and when it exceeds safe limits, it can pose significant risks to equipment, personnel, and the environment. That's where pressure safety valves (PSVs) come into play.

Introduction:

Pressure is a critical factor in various industrial processes, and when it exceeds safe limits, it can pose significant risks to equipment, personnel, and the environment. That's where pressure safety valves (PSVs) come into play. These essential devices play a crucial role in safeguarding against excessive pressure, preventing potentially catastrophic failures and ensuring operational safety. In this blog, we will explore the importance of pressure safety valves, how they function, their types, and their significance in various industries.

Understanding Pressure Safety Valves:

Pressure safety valves, also known as pressure relief valves (PRVs), are mechanical devices designed to automatically relieve excess pressure within a system, thereby protecting it from potential damage or failure. These valves are typically installed in pipelines, vessels, and other equipment where pressure regulation is essential.

Function and Working Principle:

The primary function of a pressure safety valve is to open when the pressure inside a system exceeds a predetermined set limit, often referred to as the "set pressure." When the pressure surpasses this limit, the valve's mechanism is triggered, causing it to open and divert the excess fluid or gas to a safe outlet. This rapid pressure relief helps prevent over-pressurization and potential accidents.

Types of Pressure Safety Valves:

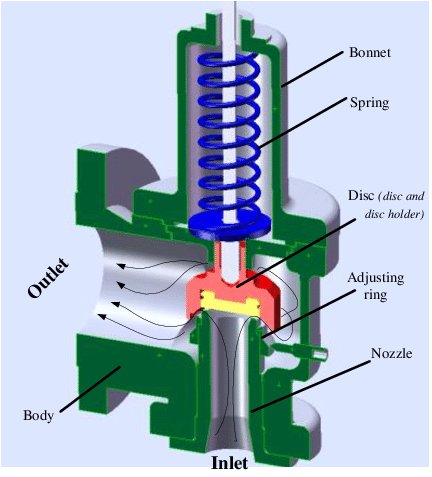

Spring-Loaded Valves: These are the most common type of pressure safety valves. They consist of a spring-loaded disc that is held against the valve seat by an adjustable spring. When the set pressure is exceeded, the spring compresses, allowing the disc to lift and release the excess pressure.

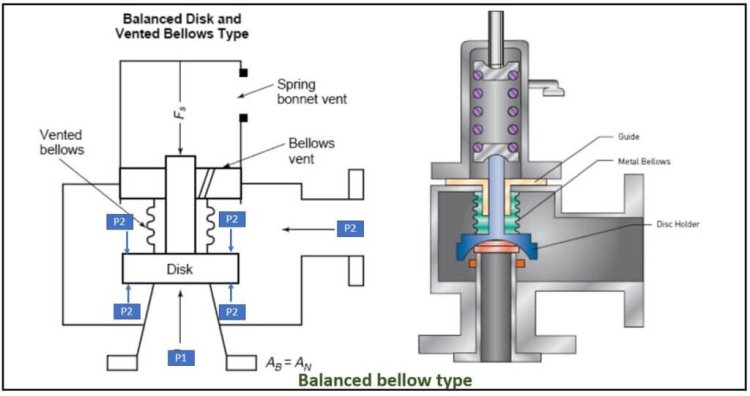

Balanced Bellows Valves: These valves are designed for applications with high backpressure. They use a bellows element that is exposed to the system pressure on one side and the backpressure on the other. The balance between these pressures allows the valve to operate effectively, even in scenarios where the inlet pressure is close to the outlet pressure.

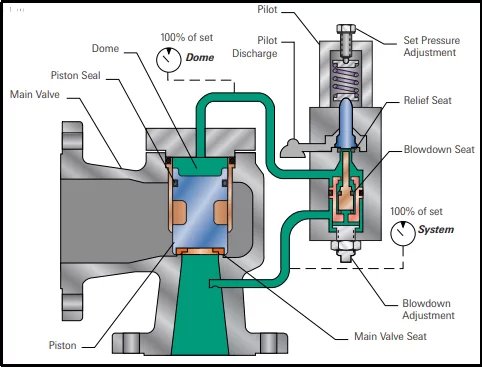

Pilot-Operated Valves: Pilot-operated valves are used when higher pressures or larger flow rates are involved. These valves employ a separate pilot valve that controls the main valve's opening and closing. The pilot valve is sensitive to pressure changes and signals the main valve to open when the set pressure is exceeded.

Importance of Pressure Safety Valves:

Equipment Protection: Excessive pressure can cause damage to pipes, vessels, tanks, and other equipment. Pressure safety valves prevent these potential failures by automatically relieving the excess pressure, ensuring the integrity and longevity of the equipment.

Personnel Safety: High-pressure releases can lead to dangerous situations for personnel working in the vicinity. Pressure safety valves mitigate the risk of explosions, ruptures, or other hazardous incidents, protecting the well-being of the workforce.

Environmental Protection: Certain processes involve handling hazardous or toxic substances. In the event of a pressure surge, a rupture could release these substances into the environment, causing severe ecological damage. Pressure safety valves prevent such occurrences by promptly diverting the hazardous materials to safe disposal systems.

Compliance with Regulations: Industries must adhere to various safety standards and regulations. Pressure safety valves play a crucial role in ensuring compliance with these guidelines, providing companies with peace of mind and avoiding potential legal consequences.

Conclusion:

Pressure safety valves are essential components in maintaining operational safety in a wide range of industries. By automatically relieving excess pressure, they prevent equipment failures, protect personnel, and safeguard the environment. It is crucial for businesses to understand the importance of pressure safety valves, invest in quality valves appropriate for their systems, and ensure regular maintenance and testing to guarantee optimal performance. Prioritizing pressure safety valve implementation contributes to a safer work environment and protects valuable assets in industrial processes.

What's Your Reaction?